Safety and Mobility

Longer Lasting Metals for Automotive Manufacturing

Laser peening can safeguard engine components to keep automotive production and manufacturing lines humming.

Automotive Applications

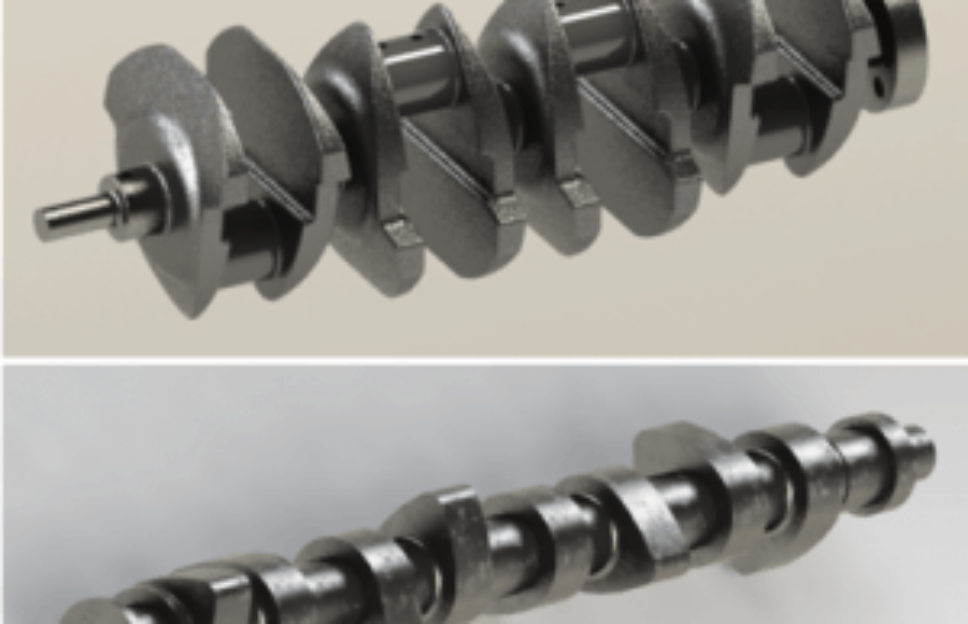

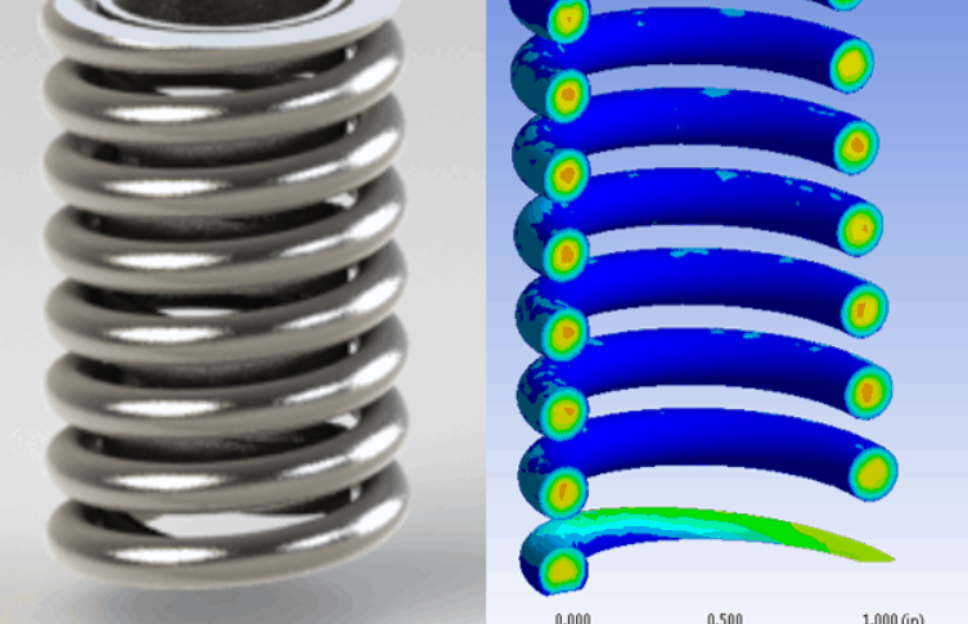

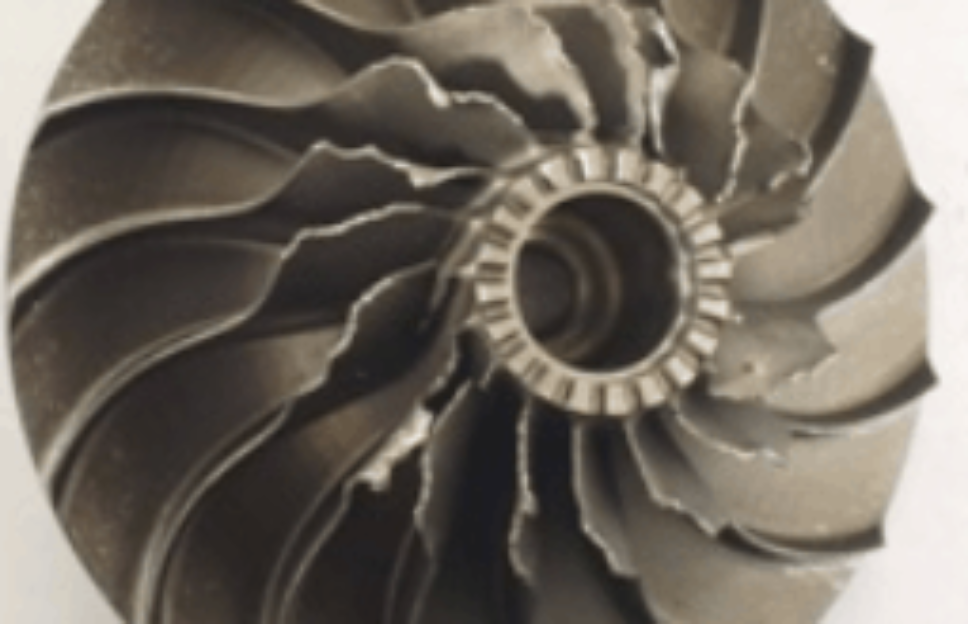

Laser peening is applied to improve material characteristics and performance of many automotive and truck parts.

- Rotating Components

- Valves

- Transmission Gears

- Axles

- Crankshafts

- Impellers

- Springs

- Turbochargers

Auto parts share a 10x longer lease on life from laser peening, just like other components, even at high motor temperatures, where thermal fatigue can impose a high cost of failure.

Don’t see your application?

Contact Us

An Edge in Automotive Solutions

On the production line or in competitive vehicle componenets, laser peening protections make parts last longer.

- Up to 10x Component Life Improvement

- Prevents Costly Failures

- Precisely Controlled and Localized Process

- Decreases Downtime

- Enables the Design of Lighter Weight Components

- Reaches a Depth 10x Deeper Than Other Surface Enhancement Technologies

We Are Trusted For Automotive Manufacturing

When you are seeking the absolute top performance, laser peening offers many benefits that are worth exploring. Whether your goal is to run the engine harder, faster, or longer we are here to discuss your needs and goals and work towards engineering a solution.

Take a Look at Some Automotive Examples and the Impact of Laser Peening

Get the Edge in Automotive Solutions

Let’s have a preliminary conversation to help you identify the tools, skills, and processes from LSP Technologies that meet your requirements – from preventing metal fatigue to measuring composite bonds. Laser peening will give you the edge in automotive manufacturing and improvement.