Power Generation

Reliability in Demanding Environments for Energy Production

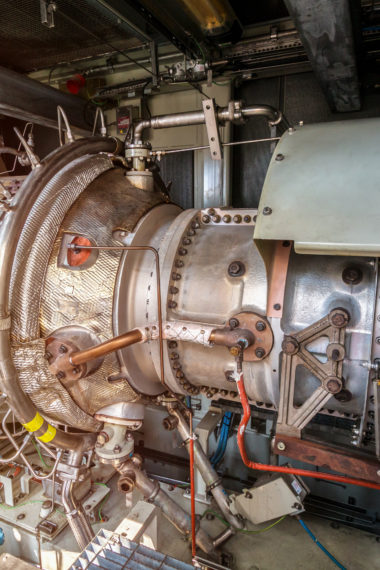

Let's Talk About Your ApplicationLaser peening extends the useful life of gas combustion turbine blades. And in the nuclear power industry, we bolster the reliability of welded parts. Top electric power industry experts endorse both solutions.

Power Generation Applications

Laser Peening has become a widely adopted surface enhancement solution for critical component improvement in land-based gas and steam turbine generators. The process has also been adopted to treat weldments and containment vessels for nuclear power systems.

Laser peening can demonstrate material improvements in a variety of metals including: titanium alloys, steel alloys, stainless steels, nickel alloys, aluminum alloys, carburized and nitrided steels.

Don’t see your application?

Contact Us

Mission-Critical Performance and Reliability

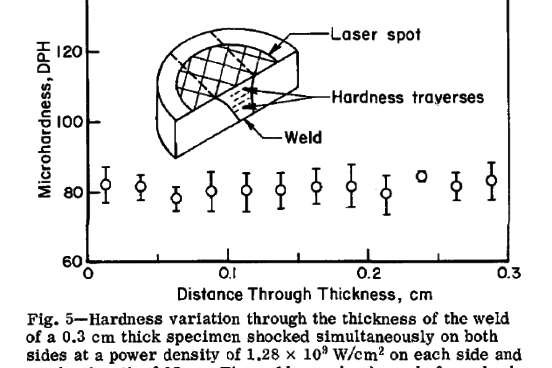

Laser Peening has gained wide recognition as one of the most effective stress mitigation strategies for power generation components.

We can test and confirm key stress points in your system, model the microstructural effects, and develop metal fatigue mitigation strategies to add reliability and years of life to your generation components.

- Up to 10x Component Life Improvement

- Powerful Resistance to PWSCC Fatigue

- Precisely Controlled and Localized Process

- Surface Enhancement in Hard-to-Reach and Hazardous Environments

- Reaches a Depth 10x Deeper Than Other Surface Enhancement Technologies

Take a Look at Some Real-World Examples of the Impact of Laser Peening

How can laser peening make your power system components last longer?

Reliability is paramount in power generation equipment, and the weakest link can sink major systems.

Please tell us a little about your most challenging issues, and we’ll start working on laser peening solutions to match.