Laser Bond Inspection Equipment

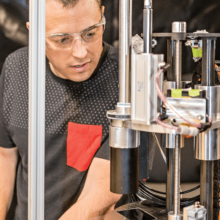

Advanced equipment to ensure safety and quality for composite bonds

Advanced lasers and fiber optics provide new cost-effective equipment options for Laser Bond Inspection.

Ongoing LBI technology and innovation provides the opportunity for LBI inspection heads that are even lighter and more compact. Composite designers and engineers will find innovative applications, knowing they can ensure quality and safety of composite adhesive bonds.

With decades of experience in high-energy pulsed lasers, successful technology demonstrations at major manufacturers, and nearly 20 years of laser bond inspection experience, LSP Technologies can provide durable, reliable, and accurate non-destructive Laser Bond Inspection equipment.

The Next Generation of Laser Bond Inspection Equipment

- Advanced diode-pumped lasers for precision beam delivery

- Smaller, easier-to-maneuver inspection heads

- New custom tooling for hard-to-reach inspection spots

- Fiber optic laser delivery adds flexibility, cuts weigjht

- Improved software and measurement tools for real-time testing

Technology Proven at Major Aerospace Organizations

Meeting demanding standards for composite adhesive bond testing.

- The Boeing Company,

- Northrop Grumman

- US Air Force Research Laboratory

Innovation and Laser Bond Inspection Expertise at LSP Technologies

- Patented Laser Bond Inspection process in 2002

- Successful development and demonstrations completed, 2004-2010

- First system delivered to Boeing in 2012

- New LBI system dellivered to Northrop Grumman in 2017

- Aggressive roadmap for next-generation LBI, 2018-2020

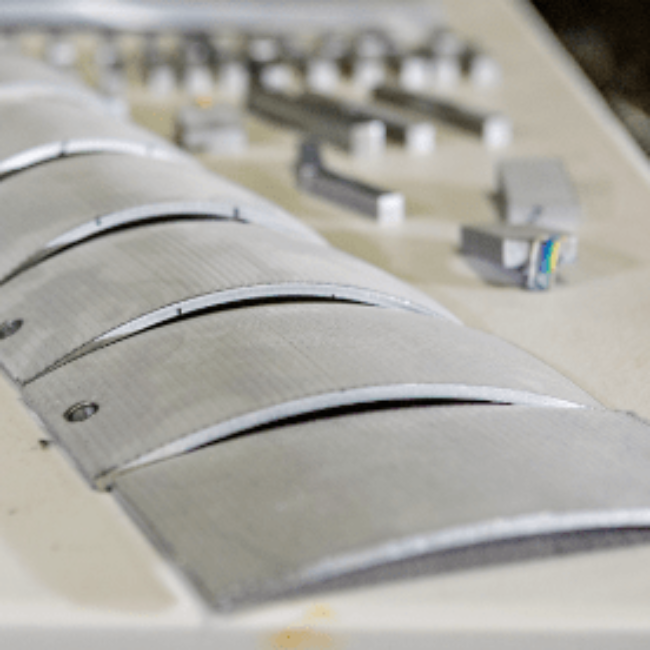

LBI Equipment Designed to Meet Customer Requirements

Choose from Two Models

LBI 30

30-Joule system

25 mm Free Path

LBI 10

10-Joule system

12 mm Free Path

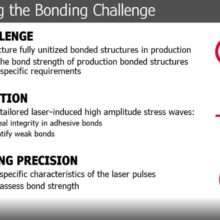

Learn More About Laser Bond Inspection

The latest brochure describes the many benefits of Laser Bond Inspection for non-destructive testing of composite adhesive bonds.

Aerospace, Power Generation, and Automotive composite components will improve in quality, consistency, and durability, with the assurance of Laser Bond Inspection.

And we describe the unique technological advantages of LBI for detection of sub-standard bonds and kissing bonds — materials that are in intimate contact, but have no mechanical bonding strength.

Customized Laser Bond Inspection Equipment

Each portable Laser Bond Inspection System can be tailored to a specific application. Using specialized tools, snapping on to fiber optic cables, a single system can accomplish tasks for multiple applications and components.

- Size and accessibility of area to be LBI inspected

- Thickness and geometry of bond

- Number of inspection points per day

- Mobile or stationary LBI Solution

- Move the Beam to the Part or the Part to a Fixed Beam

- Real-time test data and bond line evaluation

Explore Quality Assurance With Laser Bond Inspection for Non-Destructive Testing of Composites

Major aerospace manufacturers and defense aviation experts now agree Laser Bond Inspection has the potential to dramatically improve quality insurance for composite adhesive bonds.

The excitement now extends to commercial customers in a wide range of industries with their own demanding composite bond applications. Laser Bond Inspection provides the precision and ease-of-use you would expect from LSP Technologies.

To find out more about Laser Bond Inspection, please tell us a little about your application, and our highly qualified application development consultants will develop a cost-effective plan to improve quality assurance for your composite bond application.