Air Force Research Laboratory Touts Laser Bond Inspection

Finding new ways to save time in manufacturing and increasing aircraft range is an uphill challenge. Bonded composite structures enabled by LBI are a step in the right direction.

Posted: February 6, 2018

By:

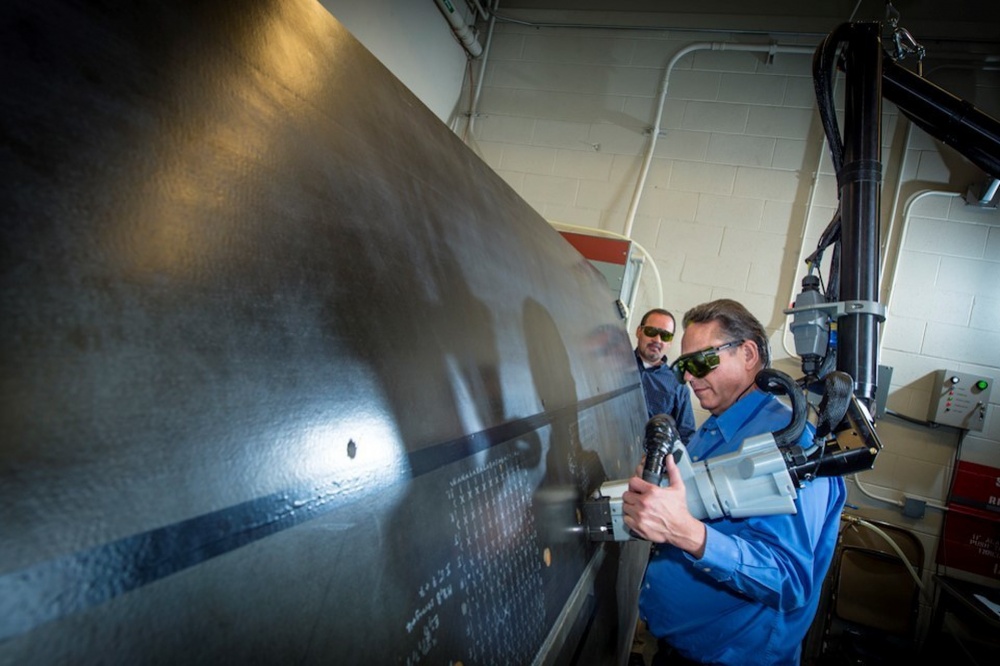

Laser Bond Inspection (LBI) is a nondestructive inspection method for evaluating bonded composite structures. The U.S. Air Force and The Boeing Company are currently using LBI to develop composite airframe designs and manufacturing processes. The Air Force Research Laboratory, located at Wright-Patterson Air Force Base in southwest Ohio, recently published an article highlighting the capabilities of LBI, and the industry impact of reliable composite manufacturing.

A highlight from the piece:

LBI is the only reliable and mature method capable of assessing the integrity of adhesive bonds in composite structures and detecting kissing bonds, a bond line defect where two surfaces are in intimate contact but are not properly bonded.

You can read the original article here. Full text by Donna Lindner of the Air Force Research Laboratory below:

Air Force Collaboration Could Increase Use of Composites in Aerospace Manufacturing

Bonded composite airframe structures offer a potential to achieve more affordable manufacturing and more efficient structures, ultimately meeting the goals of the Air Force for increased range and reduced fuel consumption.

Laser Bond Inspection (LBI) in conjunction with bond process control is an enabling technology to transition primary bonded composite structures and realize these goals.

Composite structures, when joined using adhesive bonding rather than traditional rivets or fasteners, require a new inspection process to verify the strength and safety of the composite bonds.

LBI is a stress test to ensure that adhesively fastened structures are joined correctly using a bond’s response to a high-energy pulsed laser generated stress wave to detect structurally substandard bonds.

A weak, improperly prepared bond will be broken by the pulse, but a standard bond will remain unchanged after pulse excitation. Substandard adhesive bonds can result from errors created by poor adhesive mixing, improper surface preparation or contamination.

LBI is the only reliable and mature method capable of assessing the integrity of adhesive bonds in composite structures and detecting kissing bonds, a bond line defect where two surfaces are in intimate contact but are not properly bonded.

“This effort is a significant progression of more than a decade of collaboration and development work by the U.S. Air Force, The Boeing Company, LSP Technologies, and additional major aerospace original equipment manufacturers,” said Andrea Helbach Structures team lead in AFRL’s Materials and Manufacturing Directorate.

“However, it is far from finished. On-going efforts will prove the technology on multiple representative aircraft structures and prototype a fiber optic delivery system to increase device reach.”

Future work in this technology area includes analyzing data for bond integrity in the field. Tests also need to be done to define a wider gamut of materials, thicknesses, and joint designs so the technology can be expanded to other platforms. Additionally, hardware improvements must be made to the Laser Bond Inspection unit for usability in a manufacturing environment.

This technology, along with a Defense Advanced Research Projects Agency program to establish bond process control, are significant steps in enabling bonded aircraft structures use in the field.

Finding new ways to save time in manufacturing and increasing aircraft range is an uphill challenge. Bonded composite structures enabled by LBI are a step in the right direction.

Contact LSP Technologies

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.