Transparent Overlay for Laser Peening

In the application of laser peening, two overlays are applied to the surface to be laser peened: opaque and transparent.

Posted: November 10, 2015

By: wpengine

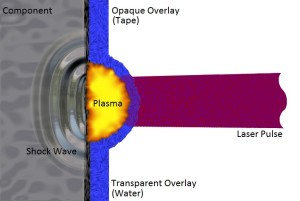

In the application of laser peening, two overlays are applied to the surface to be laser peened: opaque and transparent. Both are employed to improve the effectiveness of laser peening. The first overlay that is applied to the surface is an opaque overlay, typically aluminum or black vinyl tape, which absorbs energy from the laser pulse and generates a high-temperature plasma of 10,000o C. The second overlay is transparent to the laser beam, typically flowing water, acting as a tamping mechanism to confine the expansion of the plasma. An illustration of the process is shown below. As the plasma blows through the water, a shock wave is created that enters the surface of the part, plastically deforming the surface and producing a compressive residual stress field that enhances the fatigue properties of the part.

The surface of the part is protected from the high temperature plasma by the tape. During the life of the very short laser pulse, typically less than 30 billionth of a second, there is insufficient time for the plasma to burn through the tape and damage the part. The water has no effect on cooling the high temperature of the plasma during this short period. The water is used to intensify the shock wave by tamping the expansion. By acting as a momentarily tamping mechanism, it increases the intensity of the shock wave and its lifetime – thus enabling the production of a deeper and more intense residual stress field.

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.