Patents reveal history of laser peening innovation at LSP Technologies

LSP Technologies is responsible for more than 60 laser peening patents. The adoption of laser peening to protect B-1 bomber jet fan blades set off an explosion of patents and innovation for the fledgling industry.

Posted: December 18, 2019

By:

The 70-plus patents awarded to the staff of LSP Technologies, Inc. (recently added in full to the company’s website at https://lftcglobal.com/patents-in-laser-peening-and-laser-bond-inspection/) ranks as a remarkable achievement for a company that employed only 20-30 people during most of its 25-year life span.

Today, 60 people work at the Dublin, Ohio headquarters of the company. But in its earliest days, LSP Technologies rented space at the prestigious Battelle Memorial Institute near the campus of The Ohio State University.

Origins of laser peening technology and patents

Back then, the course of laser peening commercialization was hard to predict. The story of innovation in laser shock peening began with its invention in Russia in 1962, as well as early advances in the science at Battelle in the early 1970s. The world took little notice of laser peening until 15 years later, when LSP Technologies began its work with GE Aircraft Engines and university researchers around the world realized the technology’s time had come.

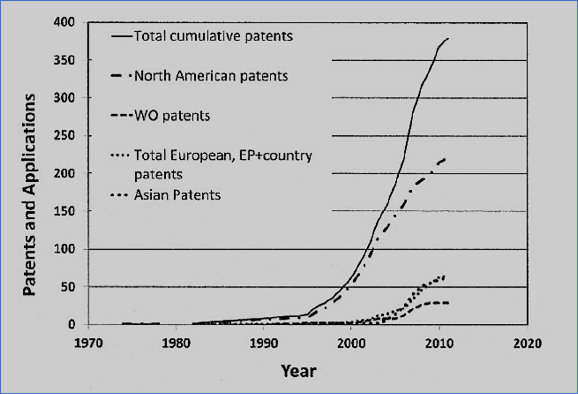

Together, they sparked a flow of innovation, patents, and competition that led to a rapid explosion in laser peening patents, beginning in the mid-1990s, and Allan Clauer of LSP Technologies documents the major steps forward in a recent article, “Laser Shock Peening, the Path to Production,” which appeared in the June 6 issue of Metals – Open Access Journal.

In 2012 the total patents reached 380, representing 15 countries, with the major regions being the United States, Europe, Japan, and China. The number of technical papers related to laser peening follows a similar trajectory, growing slowly until the mid-90s, then rapidly accelerating. At this time the number of technical papers concerning laser shock processing is approaching 800–1000, representing the research of tens of laboratories.

Allan Clauer, “Laser Shock Peening, the Path to Production,” Metals Open Access Journal

The LSP Technologies patents were from several employees. In addition to LSPT founder and President Jeff Dulaney, named on many patents, the inventors list includes Allan Clauer himself, a veteran of 34 years at Battelle and 18 years at LSP Technologies before retiring in 2014.

Boeing shares LBI patent credit

Other LSP Technologies inventors included David Sokol, currently director of research, David Lahrman, VP of Business Development, Richard Tenaglia, Steven M. Toller, Craig Walters, Mark O’Loughlin, and Steven Dykes, several of them former employees. LSPT staff also filed patents jointly with members of the Boeing Company based on their inventions of key processes in laser bond inspection.

Many of the patents involve the practical aspects of laser peening, including the use of protective coatings and media as ways to both protect parts and contain the laser-initiated plasma explosion. Others mark out the intellectual property behind laser bond inspection, the non-destructive process of verifying the integrity of composite material adhesives. There is even a strategy to detect and neutralize buried land mines with solid state lasers.

In his retelling of the research and development story, Clauer concludes that the age of laser peening patents and other innovations in related technologies is far from over, as long as the benefits can justify their costs.

“Some of these are metal forming of small objects such as MEMs (microelectricalmechanical systems) components, welding of dissimilar metals for small assemblies, surface imprinting of shape memory alloys, laser peening additively manufactured parts and using thermomechanical processing, i.e., laser peening at elevated temperatures, where it contributes to higher compressive residual stress and strength,” Clauer concluded.

Subscribe to stay up to date with the latest news and research

Access The White Paper for Return on Investment

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.