Laser Peening of Weld Zones in Aluminum Alloys

Using high energy, pulsed laser beams to shock-harden weld zones

Posted: April 18, 1976

By: wpengine

Originally published by Metallurgical Transactions A, 8A, 1871-1876 (1976). “Effect of Water and Paint Coatings on the Magnitude of Laser-Generated Shocks,” Optics Communications, 18 (4), 588-591 (1976).

Authored by Allan H. Clauer, Barry P. Fairand, and B. A. Wilcox

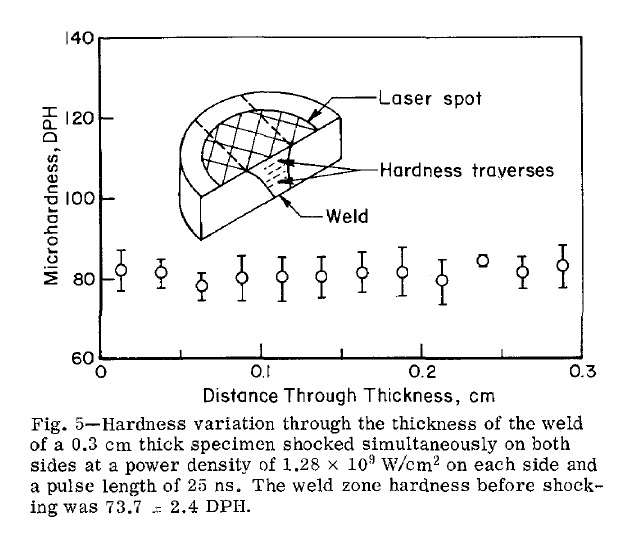

The feasibility of using a high energy, pulsed laser beam to shock-harden weld zones in 5086-32 and 6061-T6 aluminum sheet was investigated. The tensile strength, hardness, and microstructure of samples 0.3 cm thick were studied before and after laser shocking. After laser shocking, the tensile yield strength of 5086-H32 was raised to the bulk level and the yield strength of 6061-T6 was raised midway between the welded and bulk levels. The increases in ultimate tensile strength and hardness were smaller than the increases in the yield strength. The microstructures after shocking showed heavy dislocation tangles typical of cold working.

In many welded aluminum structures, the weld and its adjacent heat affected zone (HAZ) are a region of weakness having a lower strength than the rest of the structure. The strength of this region can be increased by a post-weld heat treatment or by mechanical working, such as rolling the weld bead or explosive shocking.1 However, these approaches are often either not practicable or are undesirable. Recently, another approach, laser induced shock hardening of the weld zone, has become a possibility. It was demonstrated earlier that a high energy, pulsed laser beam could strengthen 7075 aluminum alloy sheet,2 and the feasibility of using the laser to shock harden weld zones in 5086 and 6061 aluminum alloys is demonstrated in this paper. The use of a laser beam is attractive because the hardening can be localized to the desired region, is rapid, and can be easily adapted to numerical control.

Alloy 5086 is solid-solution strengthened (Al, 4.0 Mg, 0.45 Mn, 0.15 Cr, wt pct), is not age hardenable, and is widely used in the cold-worked condition. Therefore, the HAZ is subject to softening by recrystallization or recovery and can only be returned to the pre-weld strength levels by strain hardening. Alloy 6061 is age hardenable (Al, 1.0 Mg, 0.27 Cu, 0.6 Si, 0.2 Cr, wt pct) and is often used in the age hardened, T6, condition. Welding this alloy not only introduces a softer weld metal into the structure, but it also causes over-aging and resolutioning in the HAZ. The weld strength can be raised by a postweld heat treatment, but this isn’t always possible in welded structures. An alternative is to raise the strength of the weld zone by strain hardening, i.e., shock hardening.

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.