Proton Radiography: real-time images for shock in metals

LSPT experts explore pRad potential for laser peening process

Posted: August 28, 2018

By:

Can you make a movie to show the shock wave created by laser peening as it travels through metal? What would it tell you about how laser peening alters metal structures and adds to fatigue life?

While X-rays can’t show laser shock waves in real time due to the density of metals, scientists working in Proton Radiography, also referred to as pRad, can use protons to penetrate dense metals to find out more about how they react to shockwaves and explosions.

Los Alamos National Laboratory researchers invited two scientists from LSP Technologies, Inc. (LSPT) to learn more and contribute to the discussion at a workshop entitled “Proton Radiography (pRad) for Materials: Mesoscale and Beyond,” in Santa Fe, New Mexico, August 27-29.

Stan Bovid, LSPT Director of Materials Research, and Micheal Kattoura, LSPT Materials Research Engineer, attended the symposium. The LSPT team discussed Laser-Driven Shockwaves in Materials, joining other experts in materials science, as well as specialists in additive manufacturing, proton radiography, shock physics, and mining.

After reading about LSPT’s laser peening process and the Procudo® Laser Peening System, the Los Alamos scientists wondered if the shock waves created in the laser peening process could be studied in more detail, Bovid said.

“Characterizing the laser peening process typically involves analyzing secondary effects such as residual stress, fatigue life enhancement, or microhardness. The key to understanding, predicting, and obtaining these benefits though is founded in the underlying laser-driven shockwave and the impact it leaves on materials. Historically, the real-time assessment of these shockwaves has been limited to 1-D analyses and mostly rely on interferometry techniques” Bovid said.

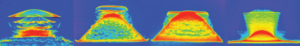

“Proton radiography, on the other hand, presents an opportunity for 2-D in-situ assessment of these shockwaves as they form and propagate. This novel technique helps fill several gaps that have long existed in predicting and understanding shockwave dynamics and opens the door for further laser peening process optimization,” he said. “The pRad team at Los Alamos has put a lot of thought into this workshop by bringing together a diverse group of experts to participate in focused discussions. We are excited to explore this technology and identify synergistic opportunities between LSP Technologies and the scientists at Los Alamos.”

Proton Radiography could provide real-time images of laser peening. Particle physicists can now use proton beams to produce images that help us travel more deeply into a wide range of metals. Magnetic lenses help focus the beams of protons.

The scientists at the Proton Radiography laboratory at the Los Alamos Neutron Science Center, where pRad was invented, have used the technique to create movies of explosions contained in sealed metal containment vessels.

Although some of the lab’s research is military in nature, they have also conducted experiments on metal surfaces to examine how damage occurs to cracked or punctured materials, which may hold pRad-based insights for both military and commercial material science applications.

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.