Fighting metal fatigue in mission-critical aviation components

We started laser peening jet engine fan blades in 1995. Other industries found value in our metal surface improvement expertise.

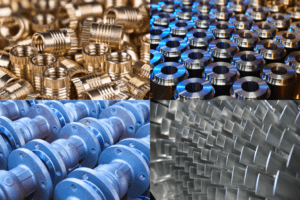

Now we increase metal fatigue life for parts in commercial aerospace, power generation, heavy equipment, performance automotive, shipbuilding, and more.

Laser peening provides distinct advantages for commercial, industrial, and government industries. We have over 150 years of combined experience in developing applications to meet the requirements for any application. If you don’t see your industry, we want to know.

Fighting metal fatigue in mission-critical aviation components

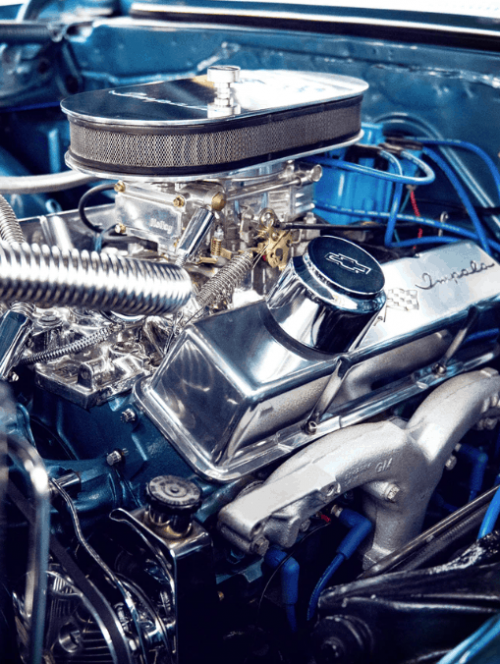

Lower downtime and reliable parts for OEMs and their customers

Laser Peening for gas combustion turbines and nuclear power

Adding reliability to construction, mining, and highway equipment

Laser Peening to extend life of pilger dies, hot and cold forming equipment

Portable Laser PeeningEequipment for shipyard maintenance and repair

Limited use of non-invasive laser surgery and limited capability in medical isotope production.

Currently, there is a huge shortage of laser technology-based training programs at colleges and universities and therefore a huge shortage of laser technology trained workforce. The joint DOE-NSF-DoD report on Basic Research Needs on Laser Technology highly emphasizes workforce development as the most crucial challenge for the US in the next 10 to 30 years.

LSP Technologies, Inc. provides laser processing services and equipment that satisfy applicable requirements and enhance customer satisfaction. We align our quality management system with our company strategies and the requirements of the AS9100D standard, and we continually improve its effectiveness.

The SAE Standard AMS-2546, Laser Peening, covers the requirements for computer controlled laser peening of metal part surfaces to induce residual compressive stresses at and beneath the surface. This standard covers laser peening known as laser shock peening, and laser shot peening.

Contact us

Every week, we are exploring new laser peening applications in new industries, from off-road bicycle frames to medical implants, oil and gas equipment, and

We believe in evaluating each application and its special requirements with fresh eyes, and we relish applying our technologies to complex manufacturing processes with a steep learning curve.

We can find out quickly how our laser-based solutions can fit your company, your products, and your customers.

Your inquiry is confidential, and we do not share your personal, product, or company information with any third party.