How to Improve Fatigue Life of Metal

Materials engineers analyze, test, and apply metal enhancement strategies to improve the fatigue life of metal. Their industrial tests and field measurements prove laser peening works harder to enhance the fatigue life of components while cutting maintenance and downtime costs.

Combating Metal Fatigue

Metal fatigue occurs when a metal component is weakened due to cyclic loading, the kind of forceful repetitive use that can cause the surface of the component to crack.

Today’s demanding mechanical processes – on the factory floor and in mission-critical parts for customer products – place high demand on component materials, so material and mechanical engineers face metal fatigue issues on a regular basis. They need reliable strategies and carefully documented design and repair parameters to increase fatigue life and prevent catastrophic failures. So how do engineers improve the fatigue life of metals?

Preventing Metal Fatigue in Engineering

Design: In order to keep the stress below the threshold of fatigue, engineers use models and experience to optimize the design of components for a long useful life. By prescribing the right alloy, thickness, shape, and grain consistency to meet cyclic loading requirements, they can ensure that metal fatigue will not lead to the overall failure of a system for the predicted life of the part. Crack growth calculations and nondestructive inspections are put in place to help ensure safety.

Testing: No component, however, is completely immune to metal fatigue failure. Materials scientists push parts to their limits, analyzing when cracks or corrosion start, and to help analyze the rate that cracks grow under a variety of realistic and simulated operating conditions. That testing helps pinpoint and explain more about failure locations and the origins of potential the cracking.

Repair: Repairing small cracks can help slow down crack growth and prevent catastrophic failure. Crack repairs are only a temporary remedy to metal fatigue. Drilling, blending, and patching are all ways that engineers repair crack growth on different surfaces of materials.

Technology To Prevent Fatigue That Engineers Turn To

Increasing the fatigue life of crack-prone components is a top priority for mechanical and materials engineers. That’s why they turn to laser peening to deliver protection deep into the surface of metal components.

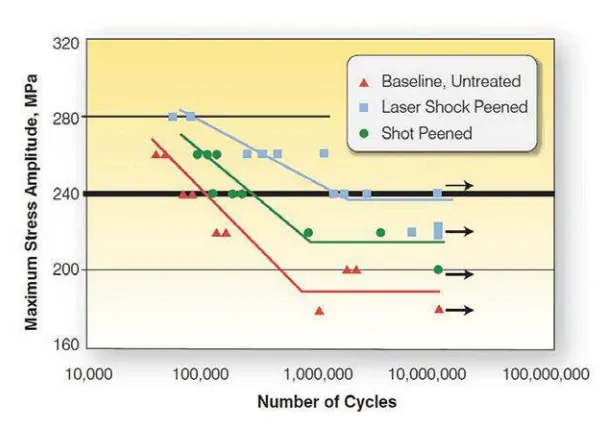

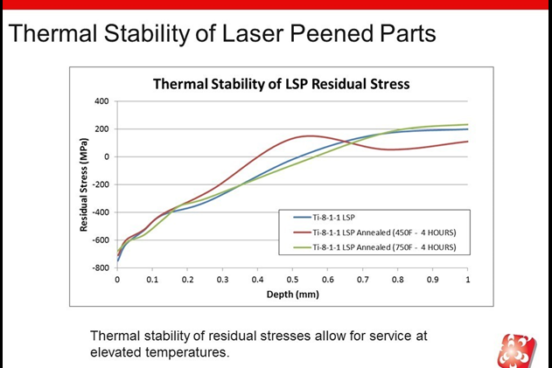

Laser peening is proven to provide deeper protection, longer component life, and higher temperature durability compared to other surface enhancement technologies.

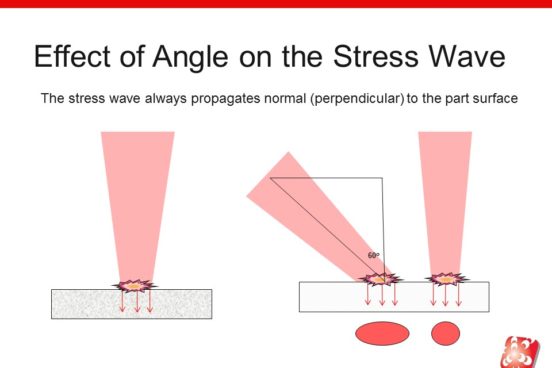

Because of the precision and power of the laser pulse, compressive residual stresses penetrate up to 10x deeper in a component. Compressive residual stresses at that magnitude and depth directly correlate to improvements in fatigue life and strength.

Engineers and manufacturers will continue to push the limits of material capabilities, and laser peening has become an invaluable technology to ensure that metal components meet the demands of fatigue life improvement.

More On Improving Fatigue Life With Laser Peening

Let’s Discuss Your Metal Fatigue Problems.

Metal fatigue can cause catastrophic failures during a critical process. Laser peening was developed to mitigate metal fatigue and give your components a longer lifetime.

Talk with our engineers to develop the perfect laser peening prescription for your application!